The Belt and Road:The Main Truss Structure of the Dry Coal Shed at Coal Storage Yard 1 of the Dubai Hassyan Project Was Capped ahead of Schedule

source:

Page view:

Time:2019-05-23

The main truss structure of the dry coal shed at Coal Storage Yard 1 of the Dubai Hassyan Project was capped ahead of schedule

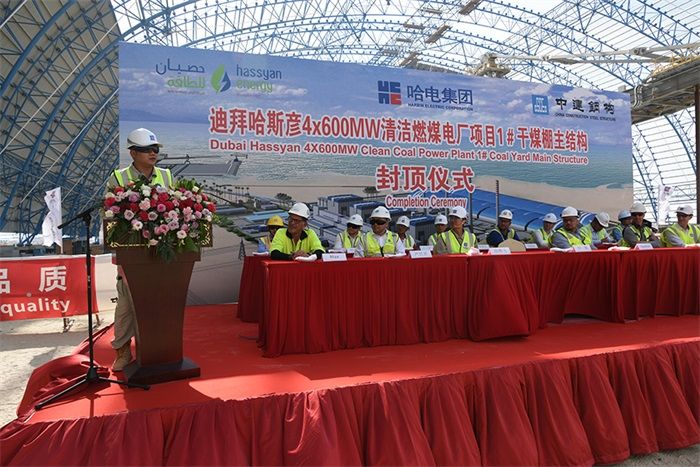

At 14:00 on May 22 local time in Dubai, the Dubai’s Hassyan 4x600MW Clean Coal-fired Project witnessed the key milestone work — the main truss structure of the dry coal shed at Coal Storage Yard 1 of the Dubai Hassyan Project was capped ten days ahead of schedule. A ceremony was held at the site in the presence of HEI, the Project Owner Hassyan Energy, the investment partner ACWA Power and GE, as well as representatives of the parties involved in the project.

The capping ceremony was held at the project site

According to international standards and environmental protection requirements, the Hassyan Project is provided with 2 coal storage yards constructed of triangle pipe trusses + stayed cables, featured by light weight, attractive appearance and economic efficiency. For the whole structural steelworks of coal storage yards, the structural design, material procurement, processing, fabrication, construction and acceptance are undertaken in strict accordance with international standards. After the coal storage yards are completed, each yard will have a length of 677m with a span of 122m, and a floor area up to 83,000m2, equivalent to 12 standard football fields. For each yard, the steel consumption is about 8,100 tons, the total weight is equal to that of the Eiffel Tower in Paris, and the overall length of high-strength steel cables is 7,800m. Each yard, with the coal storage capacity of 570,000 tons, can cater to the continuous operation of 2x600MW units for at least 45 days.

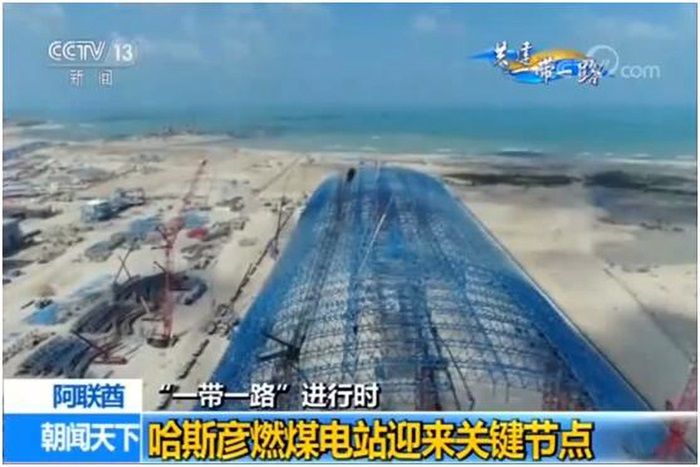

Exterior of Coal Storage Yard 1 of the Hassyan Project

From May 2017, HEI's Hassyan Project Department has collected experts and forces from all parties concerned to overcome difficulties in the structural design optimization, supply chain management and construction acceleration. In the aspect of design, the calculations were made based on the most stringent wind load parameters, and the wind tunnel test has been carried out in a German laboratory, gaining unanimous recognition from the Owner, the Dubai municipal government and other parties concerned.

Design and verification of wind tunnel tests at a coal yard by a German laboratory

At the supply chain side, the Project Department innovated the supply chain management system, made full use of international standards for real-time quality management and control, kept high-quality and high-productivity delivery and transport during the fabrication of 8,100 tons of steel structures for the whole coal storage yard, and completed the processing, delivery and transport in only 4 months. In the aspect of construction, the Project Department performed the rigorous construction analog computation and 3D construction proposal presentation before construction; eliminated some adverse factors, for instance, the high temperature in the month of Ramadan; and solved the difficulty in relation to large quantity of welding works. To weld the steel structures of single coal storage yard, the site welding equivalent was about 59,000 weld bonds, equal to the site welding equivalent of a boiler. More than 300 Chinese and foreign workers, and over 100 equipment were provided for high-speed flow-based welding, assembly and hoisting. It took 8 months to achieve such construction progress in high quality and speed with zero non-conformance being recorded. Such major milestone -- topping out of 56 main trusses of the coal storage yard -- has been completed 10 days ahead of the original schedule.

Steel structure construction at Coal Storage Yard 1 of the Hassyan Project

On April 1, “The Belt and Road in Progress” in China’s CCTV Morning News reported the progress of the Hassyan Project, and specially the steel structure construction at Coal Storage Yard 1.

At the capping ceremony, the Project Owner highly commended HEI for its project execution capability. Hashim, the Owner’s Executive President, showed his great gratitude to HEI and its construction team, and said “the topping out of the Coal Storage Yard #1 truss structure is a great achievement and we shall be proud of doing so!” Frank Hess, the Owner’s Construction Director, expressed that Hassyan coal storage yards are the most spectacular structure he has ever seen, and showed his appreciations to HEI for allocating numerous resources and sparing no effort to complete the construction of coal storage yards on schedule.

Hashim, the Owner’s Executive President delivered a speech

Li Chao, Vice President of HEI, highly appreciated the vigorous support from all parties concerned, and said “Only standing in the coal yard, can we really understand its grandeur and magnificence. This structure shows us how diligent, intelligent and painstaking HEI’s project team is. We believe all the milestone work of the project will be completed on schedule, the synchronization and power generation will be successfully carried out, and the plant will be put it into commercial operation on time.

Li Chao, HEI’s Vice President, delivered a speech

The successful capping of the main truss structure of the dry coal shed at Coal Storage Yard 1 of the Dubai Hassyan Project indicates the construction of coal storage yards, as one of the core single-structure public utilities for the Hassyan Project, has entered the final phase, and will be completed in a short time to receive the first batch of imported coal. It provides powerful guarantee for smooth operation of coal transmission system and first coal firing of boilers of the Hassyan Project and lays a solid foundation for grid connection of the project on schedule and successful taking over of Unit 1.

The whole-process construction of the coal storage yards not only reflects the capabilities of China in “Designed by China” and “Made by China”, but also presents HEI’s capability and ability to undertake the design, procurement, manufacture and construction of large integrated and complex projects. It is a brand demonstration project for “Made by China” walking into the Middle East market and even the global high-end electric market, for China’s technologies “Going Global”, and for Chinese enterprises enhancing their international images.